We are heavy metal detectors

Geoenvironmental

Ground & Water Director, Fran Williams, is committed to finding clients, the quickest, simplest, most sustainable and cost effective solutions. Here he outlines how some applied physics and clever hardware, can save time and money when it comes to contaminated land.

Ground & Water Director, Fran Williams, is committed to finding clients, the quickest, simplest, most sustainable and cost effective solutions. Here he outlines how some applied physics and clever hardware, can save time and money when it comes to contaminated land.

Back in December we presented a case study where the use of an X-Ray Fluorescence Analyser (XRF) helped our client out of a small hole, associated with the importation of potentially poor-quality Topsoil.

https://www.groundandwater.co.uk/case-study/topsoil-testing-trails-and-tribulations/

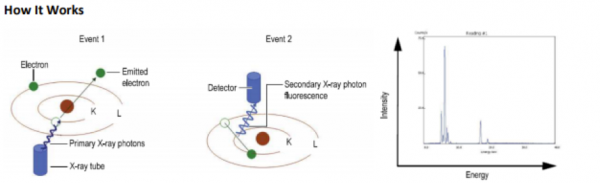

Since then Ground & Water has been involved in a number of projects where XRF analysers have been used to facilitate a speedy response to contaminated land issues. More on that later, but first a bit of background. The XRF Analyser exposes in-situ soil or samples to a primary X-Ray beam which induces elements to emit or fluoresce an X-Ray in response. Each element fluoresces at a particular point on the detectable X-Ray energy spectrum. From the peaks in the spectrum the analyser calculates the concentrations of the detectable metal elements that are present.

Since then Ground & Water has been involved in a number of projects where XRF analysers have been used to facilitate a speedy response to contaminated land issues. More on that later, but first a bit of background. The XRF Analyser exposes in-situ soil or samples to a primary X-Ray beam which induces elements to emit or fluoresce an X-Ray in response. Each element fluoresces at a particular point on the detectable X-Ray energy spectrum. From the peaks in the spectrum the analyser calculates the concentrations of the detectable metal elements that are present.

Standards

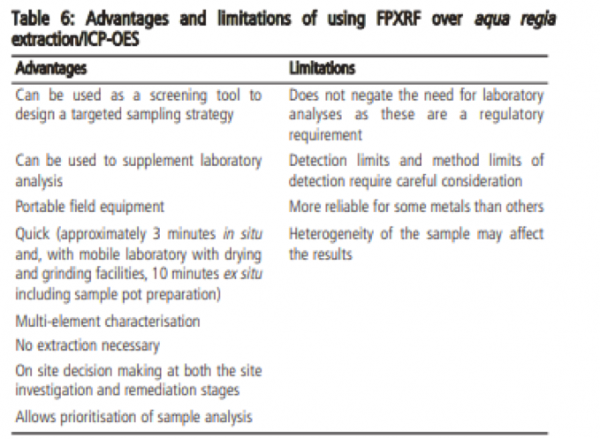

CL:AIRE Research Bulletin RB7, referencing some early work by Argyraki et al (1997) and the USEPA, concluded that the Dual Source FPXRF instrument was able to produce definitive quality data for Arsenic, Cadmium, Copper, Manganese, Lead and Zinc and the X-ray tube FPXRF instrument was able to produce definitive quality data for Lead, but achieved a low accuracy in the measurement of Nickel and Cadmium.

CLAIRE’s summary of its main advantages and limitations is presented below.

There is no specific British Standard for the use of XRF analysers; however, the Environment Agency has produced a framework for the use of rapid measurement techniques in the risk management of land contamination (March 2009) now revised in the Environment Agency new guidance on Land Contamination Risk Management (LCRM).

Conclusions:

Based on our experience, the big advantage of the XRF Analyser is during the construction phase. Should expected or unexpected metallic contamination be identified, it provides a quick and relatively inexpensive (given the quantity of data obtainable in one day) way of assessing and/or delineating the problem and defining a remedial strategy. This could then be followed up/confirmed or validated by laboratory-based testing.

What it removes is the requirement, following site works, for the three to five day wait for the results, which during the construction and validation stages, can be critical. Decisions can be made on a remedial or risk assessment-based solution on the day or next day, with laboratory testing confirming or validating the XRF results.

Our use of the XRF in contaminated land solutions, shows our continued commitment to finding clients the quickest, simplest, most sustainable and cost effective solutions to contaminated land issues.