The G&W Guide to… Sample Disturbance

Geoenvironmental • Geotechnical • Industry matters

One of the key considerations when specifying a Site Investigation is sample disturbance. Here is a quick tale to set the scene:

Imagine you are a sample of soil or rock, nicely cocooned in the ground, just as you have been for millions of years. You are in your nice little confined space, when along comes a great chunk of metal that tries to pry you out of the ground. You are pushed and pulled as you are removed, and you’re subject to the sun and moisture again, and don’t have your mates surrounding you, providing support.

Let’s just say that now you won’t be a strong as you were in-situ. And this is the basics of sample disturbance.

“There is no such thing as truly undisturbed sample; defined as a sample which has not been disturbed by the boring, sampling, and trimming but has experienced stress release.” – (Ladd & Lambe, 1963).

“The validity of site investigations carried out in laboratory tests, rests solely on the quality of the samples and on how far they are representative of the stratum from which they are taken.” – (Cooling, 1949).

Disturbance can be caused by: friction, reduction of pore pressures (being brought to surface), shocking, vibration, drying during storage, and potentially during preparation.

The effects of sample disturbance

- Reduction in undrained shear strength, and therefore bearing capacity, can be 15 – 30% (Kimura and Saitoh, 1982)

- Shear modulus can be reduced by up to 20% (Stokoe & Richard, 1973)

- Young’s Modulus decreased with disturbance = More settlement

- Settlement estimated for undisturbed samples is about four to eight times the measured settlement (Broms, 1980).

How does this affect site investigation?

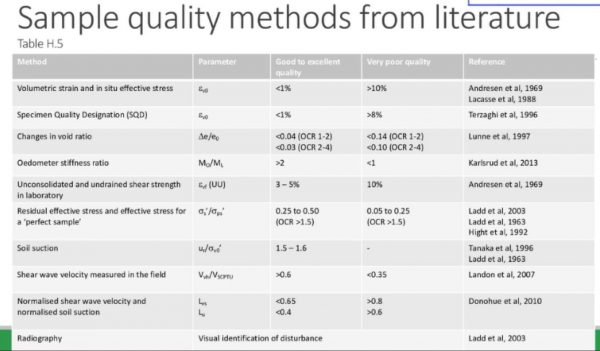

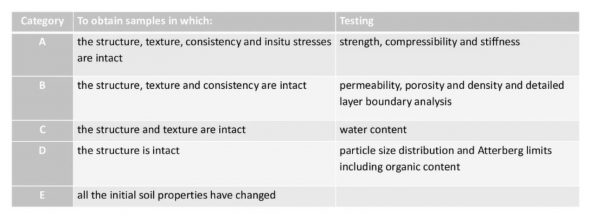

Eurocode documentation provides an overview of what quality of sample can be achieved by what sampling method. It then provides guidance on what can be done with that sample.

The codes break samples quality down into five types, with notes on what tests such a sample can be subjected to.

Below are a couple of key examples:

In order to determine the volume change potential of a soil, you need to do an Atterberg Test, which can be done on class D and above samples.

So this rules out Continuous Flight Auger boreholes. But this class of sample is generally acceptable for Windowless Sampling Rigs (Class C/D). A small disturbed tub/jar from a trial pit is also Class C/D. Hence, these are common approaches to Site Investigation.

Say we wish to undertake a Triaxial Tests on a sample recovered from a borehole. This provides an indication of a soil’s strength. We want to get the best results for our client, avoiding any potential reduction in parameters for disturbance, therefore going back to the table, we would need a category A sample. So how do we get one of those?

There are a whole host of different options, but in the Windowless/Cable Percussion sampling world we are looking at things called U38’s, U100’s or UT100’s.

The smaller diameter U38 (cable/windowless) and larger U100 (cable only) will recover Class B samples. With a UT100 it will recover Class A or B samples. Therefore, any site investigation would have to balance the extra cost of the UT version (around £70 ex VAT) against any loss of quality of information and potential conservatism in design.

Does this really matter?

Yes it does. The short case study below shows you why.

Ground & Water investigated two sites in Hackney, with Made Ground over Hackney Gravels and then London Clay from around 10m bgl to 21m bgl. A paper looked at design lines based on a site which had good quality Undrained Triaxial and SPT data and the other which had a ‘sparsity’ of such data. The costing exercise involved applying the design lines for the good and sparse data to one hundred 450mm diameter piles, looking for a 700kN working load. The depth of pile required to achieve this was 15.8m for one site (good data) and 19.8m for the sparse data. The saving was £18,000 on piling. The uplift in Site Investigation costs being nowhere near this.

Ground & Water investigated two sites in Hackney, with Made Ground over Hackney Gravels and then London Clay from around 10m bgl to 21m bgl. A paper looked at design lines based on a site which had good quality Undrained Triaxial and SPT data and the other which had a ‘sparsity’ of such data. The costing exercise involved applying the design lines for the good and sparse data to one hundred 450mm diameter piles, looking for a 700kN working load. The depth of pile required to achieve this was 15.8m for one site (good data) and 19.8m for the sparse data. The saving was £18,000 on piling. The uplift in Site Investigation costs being nowhere near this.

You must ensure that your ground engineers have the ability to use better data to its full advantage; and thankfully Ground & Water’s engineers can do that.

CLICK HERE to learn why de-valuing a Site Investigation is planning to fail.