The G&W Guide to… Poor Site Investigation

Geoenvironmental • Geotechnical • Industry matters

“Unfortunately, soils are made by nature and not by man, and the products of nature are always complex.” Karl von Terzaghi (1936).

Here at Ground & Water we love the above quote, from one of our geotechnical heroes. It sums up what we are up against and also hints at the pitfalls that can be encountered during the site investigation process.

A poor site investigation can lead to:

- Losses in time

- Poor publicity

- Financial expense

- Increased factors of safety within analyses

- Higher risk and higher tender sums.

“Of 8,000 D&B contractors, 50% experienced unforeseen ground-conditions, which affects sub-surface structure. Similar research in 2001 revealed 57% had seen difficulties at substructure stage”. The National Economic Development Office (NEDO) report 1988:

Have you suffered?

Just for a moment, consider a residential development extending over several hectares on a greenfield site, with good ground conditions anticipated. It would be quite normal (and therefore reasonable) to undertake a site investigation (SI) including exploratory holes on a 50m grid pattern. However in this scenario only about 0.04% of the soil relevant to the engineering design is sampled. The sub-samples that are tested in the laboratory will constitute about 0.00002% of the soil.

Turning this on its head… The fact that 99.96% of the nature and properties of the ground is unknown may not appear so reasonable!

Across the construction industry, approximately 0.004% of a contract budget is spent on the SI. According to research this should be in the order of 1.1%, considering it is such a vital process. And given that 95% of outside consulting engineers are appointed after the contract has been awarded, the primary contractor having committed to a fixed sum, can ‘best practice’ or ‘best value’ really be achieved?

“In order to reduce risk during sub-structure works, pre-planning site investigations work in a logical sequence, and improving communication systems between the principal parties, was vital to achieve a quantitative report, capable of meeting design requirements”. Peacock 1990.

So what factors bring about discrepancies in Site Investigation information?

A recurring issue are misleading executive summaries that overlook detail, leading to difficulties in finding key information in SI reports. But there are many other factors effecting the key stakeholders in the SI and design process.

Contractor issues:

- Tendering is an expensive process and often inadequate information is “made do with” in an effort to cut tendering overheads

- Lack of uniformity in reporting methods and procedures used to gather SI information

- Limited time to study SI information, and those tendering the overall project do not fully understand SI reports

- Inappropriate specification of SI works by those with limited experience or expertise to carry out such a function.

SI consumers:

- Tendering SI works stifles a flexible approach to investigative works and does not “promote” best practice or value

- Insufficient funding denies designers the level of design information they need

- SI consumers need education about the benefits of carrying out a thorough SI

- SI work must be specific to the requirements of the brief. All too often inappropriate SI information intended for basic feasibility becomes the only information available for the final design of the project

- Adequate time must be allowed for the planning and execution of a thorough SI exercise

- Failure to appoint consultants early in the project’s life cycle. Early consultation and design appraisal is paramount to the success of a project.

SI organisations:

- Failure to consult or appoint geotechnical/environmental specialists to the design team early in the projects development

- Tendering against a “shopping list of SI exercises” rather than a tailored brief

- Inadequate planning and specification of the SI processes

- Inflexible approaches are adopted from the outset, and the failure to ensure that a senior, experienced engineer is present on site to modify and request further investigative works

- Insufficient budget, to ensure an adequate and holistic SI.

So how does Ground & Water help clients avoid these pitfalls?

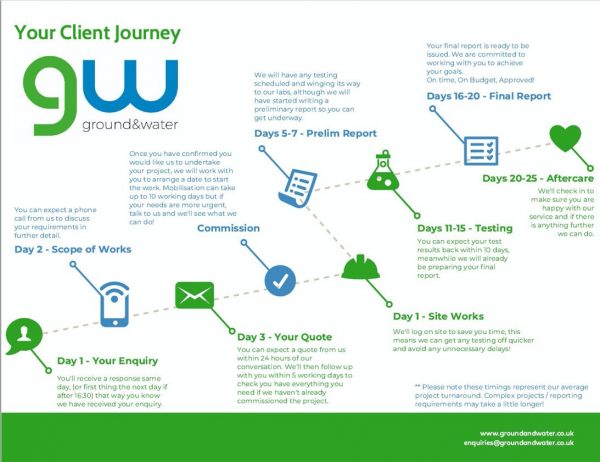

Our client journey aims to promote best practice and value: (see figure 1). It is aimed at ensuring you get the very best information about your site, in a logical sequence; all principle parties are kept fully informed at the appropriate stages and a quantitative site report capable of meeting your design requirements is produced. The key outcome is to minimise your risk during ground-works ultimately saving you time and money.

Figure 1

The pre-commission scope of works discussion is the key stage. We need to ensure we get your “Afters” (desired outcomes) and ensure your aware of how these are best achieved in the current regulatory framework.

There is nothing worse than going away from this stage with different expectations.

At the commission stage, ensure you are happy with what will go on onsite and how the site will be left afterwards.

Post Site Works: Making sure you aware of how things went and what the initial results are. It’s all about keeping you informed.

The Preliminary Report is another vital stage. Here it is vital that you consider whether the initial findings are in line with expectations and whether any changes to the scope of works are required to provide more definitive answers. It may be its all fine, but it’s good to check, before the final report is issued.

The Final Report and After Care: This is another vital stage because these are our initial recommendations, based on the work undertaken. It is imperative you understand the implications of the report and what it means for your development.