The G&W Guide to… California Bearing Ratio

Geotechnical

The California Bearing Ratio (CBR) is a measure of the strength of the sub-grade under a road or other paved area, which determines the depth of the sub-base and materials used in its construction. The ratio is measured using a standardised penetration test first developed by the California Division of Highways for highway engineering.

It is defined as the ratio of force per unit area required to penetrate a soil mass with standard circular plate at a rate of 1.25mm/min.

But basically, the lower the number the softer the sub-grade meaning a thicker road construction is required.

So if you pick the wrong type of CBR test (and there are lots of different types of tests) then your road construction could be more costly than required.

What follows is a broad guide, which is mainly based on what CBR tests to use for the “Design CBR” for a road. There are both In-situ and Ex-situ methods. The In-situ method is likely to give higher results than Ex-situ, due to disturbance, although samples are remoulded in the lab.

Lightweight In-situ tests

The In-situ Mexe Probe test – Suited only to soft to medium grained sub-grades. Inexpensive and quick to do, so several can be done in a day.

- Mexe Cone Penetrometer– Developed in conjunction with the Ministry of Defence, the Mexe Cone Penetrometer is a lightweight, reliable probe that allows a rapid measurement of CBR in fine grained soils. The test measures CBR over a range of depths up to 0.8m. This has the benefit of avoiding the need for an excavator on site and tests can be carried out in just a few minutes.

The Clegg Hammer test – This test is designed to measure the hardness or shock absorption properties of a surface. Inexpensive and quick to do so several can be done in a day.

- Clegg Impact Soil Tester (CIST) – Popular with local authorities, the Clegg Impact Soil Tester is both accurate and rapid. The test is typically carried out at the ground surface or in a trial pit and works best on fine grained soils.

The In-situ CBR DCP test – This test is more appropriate for harder/coarser sub-grades than a Mexe-Probe test. Slightly more expensive than the lightweight tests and between 12 and 15 can be done in a day.

- Dynamic Cone Penetrometer (DCP)– The DCP test measures equivalent CBR over a range of depths, typically up to 1m. This has the benefit of avoiding the need for an excavator on many sites and allows an ‘optimum depth’ to be established. Typically the test takes around half an hour and can be undertaken in cohesive or granular materials.

The In-situ CBR test – More expensive than the DCP test generally. You can do eight to ten in a day.

The In-situ CBR test – More expensive than the DCP test generally. You can do eight to ten in a day.

- In-situ CBR – A 4WD vehicle is generally used to transport the equipment and to provide the reaction load required to drive the CBR press. Measurements of applied load and plunger penetration are made at regular intervals and plotted onto a curve. The CBR bearing value is expressed as a percentage ratio against a standard soil (California Crushed Limestone) and obtained by dividing the plunger loads at penetrations of 2.5 and 5.0 mm by the loads given at the same penetrations in the standard crushed stone.

The Plate Load Test

Plate Load Tests are best suited for granular soils (CBR=6.1 X 10 -8 X (k762)1.733). They need the weight of a large machine or excavator to provide the reaction load so are comparatively expensive and you can only do six to eight in a day.

Plate Load Tests are best suited for granular soils (CBR=6.1 X 10 -8 X (k762)1.733). They need the weight of a large machine or excavator to provide the reaction load so are comparatively expensive and you can only do six to eight in a day.

A plate load test (also known as a plate bearing test) determines the ground’s modulus of sub-grade (k) reaction by applying an increasing load from a circular steel plate to induce settlement. The test results are then modified into a CBR. The great thing about these tests is it can also be modified into a bearing capacity and is a great test for ground bearing slabs.

NOTE – The reverse is not true and a CBR test cannot be turned into data for bearing capacity.

Ex-situ tests

The Ex-situ soaked or unsoaked laboratory CBR test – This test is used mainly for cohesive soils. For the soaked test, the soils are immersed in water for four days. Mid-range in terms of cost and you can send off as many samples as you wish, although the cost goes up the more samples that are collect.

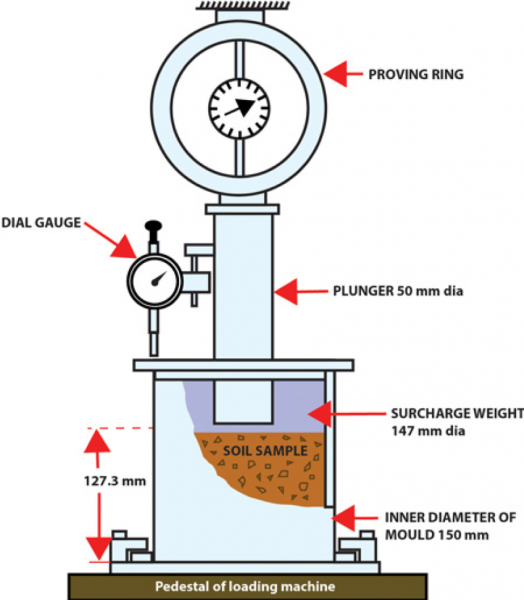

- A bulk sample is taken from site and sent to the lab for remoulding and testing. The testing method is similar to the in-situ one using a 4×4 but is done using a machine in the lab (see below). Laboratory CBRs usually result in a lower score than in-situ CBR due to sample disturbance and the remoulding. The soaked test is understood to have been development to simulate a road being submerged under water during a flood.

Equilibrium CBR Assessment – This test is based on geotechnical classification testing and uses reference literature, so is relatively inexpensive.

- From a good GI you should be able to predict the CBR of any near surface natural materials encountered. This test uses the basic engineering properties of the soil encountered (plasticity) and depth of groundwater is used to predict (using literature) the CBR of the soils.

So which test is best for what scenario?

The first question we must answer is: Are the roads adoptable? (I.e. Adopted for public use and maintained by the local authority’s highways). This is a critical question because council highways authorities have specific requirements. For example, Berkshire, Hampshire and West Sussex all suggest that the test should model the likely moisture content at the time of construction, but in reality, they like Soaked CBR’s, which are generally worst case. This is to determine the Design CBR, with checks made by DCP/Clegg Hammer or In-situ CBRs during construction to ensure that design parameters are not undermined.

If not adoptable, then the question is what is the underlying geology likely to be? And do you want to try and get the best out of your ground? For example: If chalk, or granular soils, you may want to consider the more expensive plate load test, as you will get the best results. If a small private close on River Terrace Deposits, then perhaps a DCP. If softer silts/clays are likely perhaps a Mexe-probe or similar.

The Ground & Water effect

Ground & Water’s knowledge and expertise allows us to assess the geology of the subgrade (underlying soils), prior to any tests being specified so we can advise on and conduct the correct tests to suit the anticipated geology, the situation and purpose of the road and your budget. In simple terms you don’t need to be paying to construct a subgrade and pavement fit for a Boeing 777 runway when you are building a private access road.