A Hole in One – Why getting the right drilling rig matters!

Geotechnical • Industry matters

The two most common questions Ground & Water Principal Engineer, Alice Tettmar, is asked when preparing the tenders for our services are: “Can I use nearby BGS borehole data for the pile design?” And when she inevitably says “unlikely”, the second question is always: “Okay, so how deep does the borehole need to be?”

The two most common questions Ground & Water Principal Engineer, Alice Tettmar, is asked when preparing the tenders for our services are: “Can I use nearby BGS borehole data for the pile design?” And when she inevitably says “unlikely”, the second question is always: “Okay, so how deep does the borehole need to be?”

The answer to the second question is simple: NHBC guidance suggests the borehole needs to be 3-5m below the tip of the pile base. The challenge in all this comes from choosing the right rig for the right geology, to make sure we reach the required depth. But thankfully we have done plenty, so we are ideally placed to be your trusted advisers.

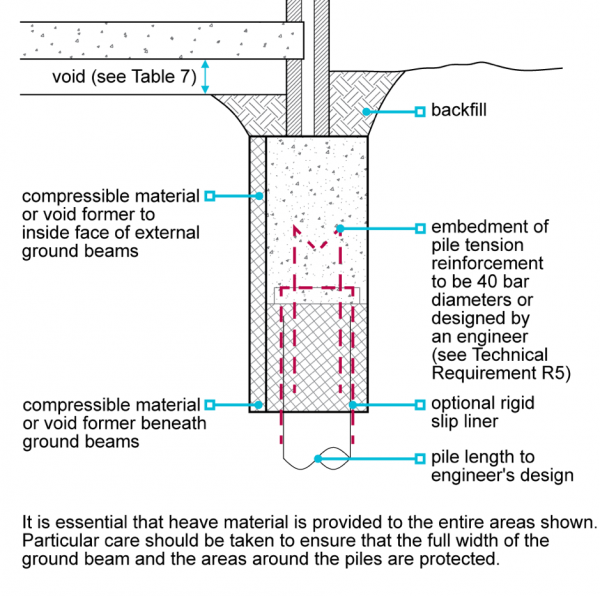

Firstly it is worth exploring what happens if you don’t reach the correct borehole depth; whether that be from refusing on the geology due to a mismatched rig or simply just not planning or designing the borehole depth correctly. Again, it’s another simple answer – cost and delays. If the borehole only gets to 12m, when the piles are going to 15m (in this case the borehole should have gone to 18-20m bgl) we are left with two risks. Either something unexpected is encountered while the piles are being installed or the build goes ahead, but then it isn’t signed off by the NHBC. Both cause lengthy delays and a potential increase in construction costs until a solution is found. (https://nhbc-standards.co.uk/4-foundations/4-2-building-near-trees/4-2-10-heave-precautions/)

Firstly it is worth exploring what happens if you don’t reach the correct borehole depth; whether that be from refusing on the geology due to a mismatched rig or simply just not planning or designing the borehole depth correctly. Again, it’s another simple answer – cost and delays. If the borehole only gets to 12m, when the piles are going to 15m (in this case the borehole should have gone to 18-20m bgl) we are left with two risks. Either something unexpected is encountered while the piles are being installed or the build goes ahead, but then it isn’t signed off by the NHBC. Both cause lengthy delays and a potential increase in construction costs until a solution is found. (https://nhbc-standards.co.uk/4-foundations/4-2-building-near-trees/4-2-10-heave-precautions/)

So how can the scenario above happen in the first place? Well, geology is variable and unpredictable at the best of times. But in our experience, it is seeing what happens when this isn’t taken into account. And sadly, this usually comes down to price and budget. Typically, the smaller and lighter the borehole rig (for example, a windowless sampler rig), the shallower (and cheaper!) the borehole. Each rig has its pros and cons depending on the geology and it’s this, that needs to be discussed at the tender stage to ensure success.

The Windowless Sampler Rig

The Windowless Sampler Rig

A Windowless Sampler Rig is best for cohesive soils and has the capability to do SPTs and undisturbed sampling. The NHBC has discounted the use of Super Heavy Dynamic Probes, so you’re now looking anywhere between 10-12m of data if the geology is forgiving. Windowless sampler rigs are very cost effective. Small, so can fit in relatively restricted areas and are good for getting coverage across the site. However, they fall down when faced with an unpredictable geology like the Lambeth Group or the Windlesham Foundation, where sand and clay bands come intermittently. They are also very likely to refuse on the dense gravel encountered flanking all of the major rivers of Southern England, typical examples include the Kempton Park Gravel Member and the Taplow Gravel Member associated with the Thames in London. Our verdict? Windowless sampling has its use, but unless we are extremely confident on the geology, it’s likely not the best match to getting the pile design borehole you need.

Cable Percussion Rigs

Cable Percussion Rigs

The next level up would be boreholes via Cable Percussion, either through the standard set up or the demountable set up. Cable Percussion can reach up to 30m in most soils, assuming that enough water is available to aid drilling and additional casing has been allowed for. It also has the capability to do SPTs and U100s and is relatively cost effective for the amount of information that is obtained. The standard rig needs a relatively large working room (6 x 4m with a 6.65m headroom requirement) which is a drawback, but this can be worked around by using its demountable counterpart, known as a Cut Down Rig. However, this comes with a higher cost to allow for mobilisation time, along with the time to set up, dismantle and remove the rig from site. In our experience, Cable Percussion is our most common way of achieving a borehole for a pile design and works well for soils like the London Clay Formation, Lambeth Group, Bagshot Formation, chalk and even some weathered Folkestone Formation, plus any capping of the dense gravels around London and Southampton. However, the disadvantages of Cable Percussion come into play where bedrocks such as mudstone, limestone and sandstone are encountered. Our verdict? Our preferred choice given the depths we can get to (as long as we can allow the correct amount of casing and access to water) and we are expecting soils rather than rock.

The Rotary Core Rig

The Rotary Core Rig

The third rig we commonly use for a pile design borehole is a Rotary Core Rig, which is perfect for when up against bedrock geology. Rotary Core drilling rigs don’t really have a depth limit, you just need bigger and more powerful rigs to get there. Some of the larger rigs can get to 150m plus. These rigs can obtain intact core samples (dependant on if drilling with water/mist/air flushes) so good for rock testing and can also carry out SPTs at 1.5m intervals. There is a fair amount of kit that is needed for a rotary rig such as an air compressor, water bowser and pump, plus allowing for waste. There is a mobilisation cost on top of the daily drilling rate so these rigs are more expensive, but for the level of information (and quality) and almost a guarantee on depth. If you want a rig to minimise risk when drilling in bedrock, the rotary rig is your best bet. Our verdict? Our choice for when drilling in dense geologies and we need full certainty that depth will be reached. It’s worth the price tag that comes with it.

As a way of comparing the above, below are some indicative costs of what you ‘might’ expect to pay per metre depending the borehole rig of choice. However, please give us a call and we can discuss your requirements so we can do the hard work for you!

| Rig Type | m Per Day | Price per m |

| WLS | 20 | £ 47.50 |

| Cable | 15 | £ 120.00 |

| Demountable CP* | 8 | £ 225.00 |

| Rotary* | 10 | £ 429.50 |

*incl. a mobilisation time and day rate so may vary.

As you can see there are multiple ways to reach the goal of a successful borehole. It just requires a risk assessment based on the geology to choose the right rig for the job. Geology is and always will be, unpredictable, so in our experience allowing for this uncertainty is vital. It’s better to spend a little more to make sure it’s all completed correctly, than to possibly cut corners and find you are short of information!

Ground & Water, will explore all the options for you and propose a cost effective, pragmatic and suitable site investigation to get you digging and your build off the ground.

Don’t just take our word for it…..

‘We have used and recommended Ground and Water regularly over the last 10 years. We have found them to be very competitive, offering fast quotations, quick lead in periods, and efficient and professional reporting’ Neil Miller, MD, Neil Foundation Systems Ltd